RENOVATION, DEMOLITION AND RECONSTRUCTION OF CENTERPOINT

Project Summary: CentrePoint Tower, built in 1971 in Central London is the subject of an assignment by Intermediate Unit 8 of The Architectural Association School of Architecture. The assignment calls for the "remodeling" or "renovation" of the tower into a new landmark that is befitting of the bustling entertainment district that The West End of London has come to be known for. The students in Unit 8 embraced many outrageous concepts, including re skinning the tower with an aluminum cylinder detailed to look exactly like an enormous Coca-Cola Can. The proposal discussed below is a replacement tower- for the original demolished CentrePoint Tower, a re planning of the traffic system and the weather system surrounding the new tower- redesigned after a process of attempting a renovation using fragments of The Queen Mary. The replacement tower design evolved out of rigorous testing of the aerodynamic properties of the replacement. The new building will produce a significant amount of its own electricity from wind baffles that correct the flow of wind from crashing down on cowering tube travelers. These baffles redirect the wind upwards by altering the air pressure at ground level and inducing laminar updraft using the Bernoulli Effect in some 18 Giant Wind Baffles detailed to belong to the family of wind sculpture by Susumu Shingu. The new tower shape, evolved after a dozen wind tunnel tests on differently shaped scale models including a final test at Kingston Polytechnic with Rolls Royce aeronautical engineer William Ross. The West End of London- redefined by a new landmark that employs the sun and the wind to derive its shape, orientation and golden panache.

AA Tutors: Peter Salter, Pascal Schoning, Warren Chalk.

Structural Engineer: Mark Whitby of Whitby and Byrd.

Aeronautical Engineer: Brian Gould of Kingston Polytechnic College of Aerospace Engineering

Aeronautical Engineer: William Ross of Rolls Royce

Work submitted for RIBA Certification: RIBA Part 1 (High Pass)

Date: July 1987

After exploring a steel intervention to the existing tower using fragments of the Queen Mary, and having those drawings displayed prominantly bu my tutor in "The Projects Review", the Architectural Association's yearbook of student projects, my tutors encouraged me to press on with the demolition and redesign of a new replacement tower at the end of my first year in the school.

The new tower would also act as a landmark for the West End of London as the existing tower does. The difference the new tower would bring to the West End would be the weather, alterations to many aspects of the microclimate of St. Giles Circus where the tower would redefine all aspects of travel through this gateway to the West End.

The New Centre Point Tower would defeat significant wind shear that is created by the existing tower. Life in the currently windswept plaza beneath the southwest facade and the circus generally would be ameliorated by a re-oriented, re-shaped, and re-invented tower that manipulates the prevailing south western wind using aeronautical engineering.

Two Aeronautical Engineers named Brian Gould and Willie Ross took an interest in the project and devised a method of testing 1:500 solid wood models in a wind tunnel using unspun wool tethered onto fuse wire. Following their method of attaching these "tell tails" to the sw facade of the various wood model shapes, over 12 different tower shapes were tested in a wind tunnel and mapped for turbulence using long exposure photography. "Tell tails" that moved due to turbulence were out of focus and stationary tell tails were in laminar flowing air and would be in focus. This way, I could map the movement of air across the SW facade and modify the building shape until up-draft was achieved, reversing the current phenomenon of 60 mile per hour winds crashing down onto pedestrians in the plaza below. In addition to the reduced air speed at ground level, temperatures also would stablize to ambient urban ground level temperatures where previously higher altitude cool air forced to the ground by wind shear created lower temperatures.

Several building shapes were modeled through this process, which was led by the aeronautical engineers from Kingston Polytechnic and Rolls Royce. The shape that resulted from this process of wind testing was a tapering, twisting shape that gathered low altitude air and channelled is upwards and around the south edge of the building shape. The effect of this building shape, which tapered and twisted like a plant rising to reorient itself into the sun became the compelling volume for which a structural strategy was conceived and developed with Mark Whitby of Whitby and Byrd Structural Engineers. The resulting building shape also required a modification to the degree of tapering in order to address urban planning issues at the intersection of Tottenham Court Road and Oxford Street. This correction to the tapering shape resulted in the addition of a scaffold of aerodynamic spoilers at ground level to enhance the updraft effect. These spoilers were modeled at a scale of 1:100 (five times larger than the initial massing models) on a 1:100 scale model of the desired building shape which was constructed of shim steel, brass angle, polycarbonate floor shapes and monofilament wire w/ polythene to simulate viscous glass facade with wind bracing. The fully assembled 1:100 scale model was placed in a wind tunnel at Kingston Polytechnic and rigged with scaled up tell tails that achieved similar updraft results as the original building shape at 1:500.

Figure 1: The Centrepoint Tower- (Context model by Google Earth)

...by Richard Seifert Architects in Central London- This tower became the subject of study by The Architectural Association School of Architecture Intermediate Unit 8 in 1984. The objective of the study was "make it better" by proposing renovation, additions, reskinning, remaking and downright demolishing the empty, relentless pile of precast masonry.

Figure 2: Replacement for the Centrepoint Tower- (Context by Google Earth/ Proposal Model & Montage by John Millard)

...I was the only student to propose a replacement for the existing Counterpoint Tower. This decision was not made lightly and was an interactive process that started with a "renovation" using fragments of R.M.S. Queen Mary I. After completing a number of anti-rational "additions" and "renovations" using The Queen Mary- the decision to demolish the tower was made in consultation with my tutors and the structural and aeronautical engineers who were co-opted into service on this long term project which spanned from 1984 to 1987.

Figure 3: Elevation derived from several wind tunnel tests and a dozen progress models at various scales. (Drawing by John Millard)

Q: What are those Susumu Shingu structures doing at the base of your building?

A: These are architectural fabric spoilers that induce the prevailing SW wind into an "updraft" across the SW facade where the current Centrepoint tower induces "downdraft". This updraft was observable in wind tunnel testing at Kingston University. The spoilers cause the air pressure at the lower levels of the building to significantly decrease due to micro-turbulence induced by the Bernoulli Effect as wind enters the orifice of each spoiler and expands from laminar flow to turbulent flow creating a funnel shaped cloud of turbulence that guides laminar flowing wind upwards.

Figure 3a: Model by John Millard of proposed Centerpoint Tower replacement.

The opportunity to build a 1:100 model of the proposal after three years of progressing this design with my tutors and my pro-bono structural, and aeronautical engineering consultants was a great privilege, particularly as one of the aeronautical engineers took a keen interest in constructing the model and assuring himself that the spoilers would be modeled to scale.

Figure 3b: Wind Tunnel Testing: Consultant Aeronautical Engineers Willie Ross and Bryan Gould provided access to Kingston Polytechnic's Wind Tunnel (Photo by John Millard)

After testing several smaller scale models at 1:500 that determined the shape and contour of the tower, the larger scale model was built at 1:100. Aeronautical engineers counseled that it would produce observable results to repeatedly test the smaller models using long exposure photography while under "wind" load using a hair dryer and un-spun wool tell tails hinged and pinned to each balsa model facade. The tell tails that were in focus despite the long exposure were in laminar flowing wind, the direction of which could be determined by the disposition of the tell-tail in the photo. The tell-tails that were out of focus due to movement from turbulence proved that there was no discernible wind direction (and hence no up-draft). By using this method, wind charts were made for each model resulting in a prototype for the larger model. Upon selection of this prototype, the base was determined to be too wide and my tutor drove a last minute adjustment to the width of the model. This upset the updraft flow when re-tested using the hair dryer and the tell-tails. Aeronautical Engineers introduced the spoilers to improve the creation of a vortex at the base, despite the reduction in width. Testing of the spoilers on the 1:100 scale model was possible using cladding for the model using monofilament fishing wire with polythene sheeting woven between the monofilament cables. The photo above is a still (reversed) from a vhs video take during the wind tunnel test which proved successful use of the spoilers since updraft was measurable on the 1:100 scale model.

Figure 4: The wind spoilers create a kinetic, sculptural building base that re-orient themselves to minor changes in the prevailing wind direction. (Drawing by John Millard)

The masts which support these spoilers tie into the primary building structure through gasket spandrel panels with the ability to accommodate movement from the pneumatic rams. These rams constrain the rotation of the spoiler to a 30 degree rotation and prevent them from slamming around. The primary structure of the building's shear walls is a bi-directional sandwich of cortex steel sheet pile filled with concrete. The shear walls change shape as the altitude of the structure increases, loading requirements change and the convex base of the envelope morphs into a compound curving/ concave shape determined by the ever changing glazing surface.

Figure 5: Section through Shell & Core (Drawing by John Millard)

Transfer Floors occur every 20m and tie the continuously rising shear walls into the concrete diaphragm that interrupts the wind bracing of the glazing system. The repetition of these transfer floors allows for MEP Distribution to occur locally creating 20m vertical zones. The horizontal Lines shown in the section represent the horizontal sheet pile that will serve as loading points for future buildout of the tenant improvements.

Figure 6: Ground Floor Plan; the definition of the building envelope is full of contrasts. (Drawing by John Millard)

Egress from the tube allows a pedestrian to surface inside the air conditioned space of the semi public "great hall" that is formed by the over-arching structure formed from rusting core-ten steel sheet pile, sandwiched together to form a fireproof core of concrete encased in corrugated steel. These ledges formed by the horizontal sheet pile create loading point for tenant improvements where transfer floors every 20m up are the only constraint to volume. The shell and core of the building are determined in this proposal with the building's fit out the subject of a future intervention.

Figure 7: Axonometric of the existing Centrepoint Tower

The horizontal slabs of space are regular and stiffened by elevator cores at opposing ends of the floor plan. This volume of space has proved to be unpopular with the leasing community due to the fact that there was very little flexibility to grow or modify use within the space. For this reason, the existing tower has been empty for several years and the building provides a landmark in the West End (and very little else).

Figure 8: Axonometric of Centrepoint Tower Showing Anti-rational Queen Mary I Forecastle Intervention

In breaking students of conventional architectural baggage, The Architectural Association School of Architecture often required students to pursue anti-rational drawings in order to convey an embarkation from the forced reality, expediency, pre-requisitism and pre-determinism of conventional commercial real estate. This hybrid ship-building conversion pushed the boundaries of absurdity- laughing out loud at the existing sensibilities and embracing with deadly serious vigor the future of London High Rises with buildings such as "The Gherkin" by Norman Foster which should be built in 20 years from the time of this project.

Figure 9: Emblematic Drawing showing Long Section of the R.M.S. Queen Mary I and the Counterpoint Tower, scaffolded with a Concordia Class Yacht protruding from the building. (Drawing by Peter Salter)

Perhaps Peter Salter became so compelled by the imaginative schemes that students were embracing at Centrepoint that he had to pick up his pen and crank out this drawing. He had already thrown down the gauntlet, challenging me to return from The Royal Institute of Naval Architects in Belgrave Square with sufficient research to hybridize the high-rise with spacial sequences from the forecastle (pronounced "FOKESAL") to the engine room to interweave within the brittle concrete skeleton of the 1970s existing building around the corner from the AA School. The drawing above was drawn by Peter after the goods were in from the RINA and we were able to make the scale association between the 1000 ft long ship and the 600 foot tall building. Once that scale association was made, Peter was off to the races.

Figure 10: Various Ships and Boats were the subject of study for construction techniques as well as scale and spatial sequences inside the hull. (Section and Elevations by John Millard)

From Top to Bottom, Left to Right: Japanese Tuna Fishing Vessel, R.M.S. Queen Mary, J Class Americas Cup, Japanese Whaling Ship, Japanese Mine Sweeper, Concordia Class Yacht, British Train Ferry. (all sections to same scale)

Figure 11: Various Ships and Boats were the subject of study for construction techniques as well as scale and spatial sequences inside the hull. (Plans by John Millard)

From Top to Bottom, Left to Right: J Class Americas Cup, British Train Ferry, Japanese Tuna Fishing Vessel, Japanese Mine Sweeper, Japanese Whaling Ship, R.M.S. Queen Mary, Concordia Class Yacht. (all plans to same scale)

Figure 12: Understanding hull lines and the transformative nature of ship design as dictated by a compelling form. (Drawing by John Millard)

Form is function when it comes to ship design- the shape of the hull largely determines the ability of the ship to displace water and to move through the water. While a building doesn't depend on it's form to "float", the thought was that a ship is beautiful and contains a program that conforms to the shape of the hull. The question we asked in our interrogation of ship design was "what shape would a building assume if wind forces largely dictated its form and how would that shape accommodate the program of the building?". (Drawing shows the aft section of R.M.S. Queen Mary I)

Figure 13: Spacial Sequence from Steering Gear of the R.M.S. Queen Mary to the Cabin Class Entry Lounge (Drawing by John Millard)

One assignment that my tutor handed out to me was to illustrate the spacial sequence from steering gear of the R.M.S. Queen Mary to the cabin class entry lounge. This sequence is a random path of travel within the Queen Marry that demonstrates a highly diverse series of spaces connected together within a highly determined hull shape resulting in functional adjacencies and complex layers of program organization.

Figure 14: Spatial Sequence from the Forecastle of the R.M.S. Queen Mary to the Engine Room (Drawing by John Millard)

Another assignment that my tutor handed out to me was to illustrate the spacial sequence from forecastle of the R.M.S. Queen Mary to the engine room. This sequence is a random path of travel within the Queen Marry that demonstrates a highly diverse series of spaces connected together within a highly determined hull shape resulting in functional adjacencies and complex layers of program organization.

Figure 15: Axonometric of the Cabin Class Entry Lounge of the R.M.S Queen Mary (Drawing by John Millard)

In particular, this Cabin Class Entry Lounge was considered by all (at the time) to be one of the most elegant spaces on a ship (or a building). Yet this space is planned in a volume of space inside the ship that is constrained by exceedingly large mechanical shafts and significant structure. The bulkheads and other appurtenances into the space create a unique, nautical scale to the space that is specific to this ship, which is open to the public in Long Beach, California. (see 1989 photos by John Millard below)

Figure 16: Montage of RMS Queen Mary Drawing and Scene from the disembarcation of a passenger ferry in Southampton England (Montage by John Millard)

Figure 17: Montage of R.M.S Queen Mary I spacial sequence on photo by John Millard of an ocean scene outside of Southhampton England

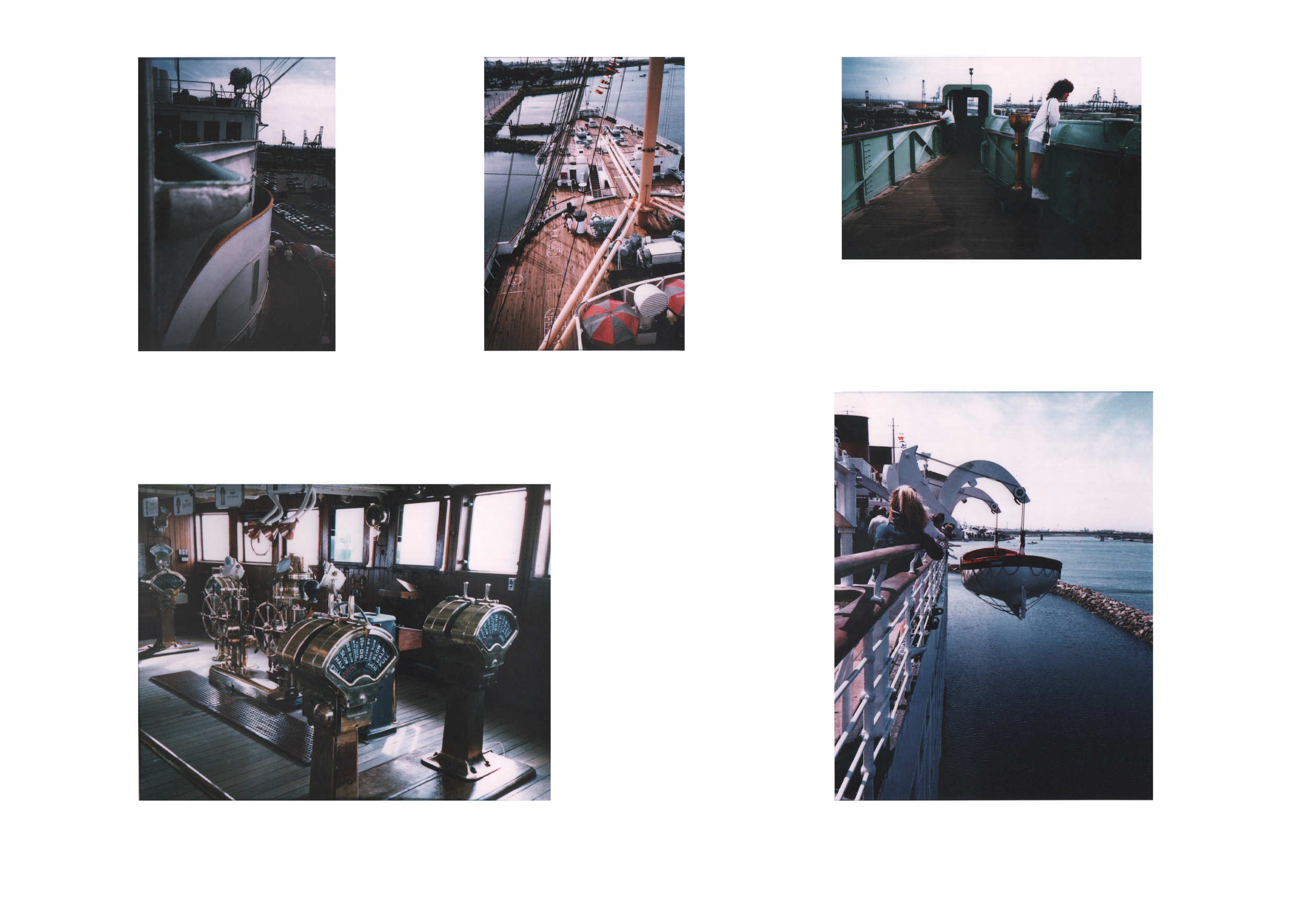

Figure 18: Photos of R.M.S. Queen Mary I

Figure 19: Photos of R.M.S. Queen Mary I (Photos by John Millard)