Neurological Research Institution associated with The Royal Institute of Neurology- Construction

Architecture Firm: Devereux Partnership

Client: Royal Institute of Neurology

Site: Queen Square, London

Date of Project: 1993- 1995

Project Summary: This new building, sponsored by The Welcome Trust and The Royal Institute of Neurology- next-door-neighbor to the site of A Functional Brain Imaging Laboratory resulted in the demolition of St. John's House, an early twentieth century convent. In its place, a medical imaging lab for the study of episodic memory and other neurological conditions that utilized PET & MRI Scanning with an on-site Cyclotron (particle accelerator) and a Nuclear Medicine Lab (Blood Gas Analysis). The building probably should have been built in a green field site, away from the city- but for the critical relationship with the Royal Institute of Neurology (next door) the project was crammed into a footprint that was difficult to coordinate ground work, utilities and foundation structure and radiation protection.

John Millard's Role- I stayed with the project throughout all phases of design to construction when I joined the construction team and followed the project to construction completion as part of my RIBA Part III Case Study. There was one other (technical) architect working with me from design development to construction documents. We both reported to a principal in charge of the project.

Specific Role by John Millard: 1) Originate all CAD drawings, 2) Lead contact with Construction Management Team, 3) Coordinate Engineering Disciplines, 4) Communicate Equipment requirements from manufacturers to engineering team. 5) Produce all Schematic Phase Drawings for approval by Owner, 6) Produce all Design Development Phase Drawings for approval by Owner, 7) Produce all Construction Documentation Phase Drawings for approval by Owner/ CM.

Chapter 8: Detail Design & Tender MRI Suite

No other section of the building suffered more conflicts of adjoining owner rights, means of escape, magneto-technical and constructional complications than in the two storey rear extention. This was especially true of the bu.~ding regulations application where there were several revisions to the fire compartmentation and the route of escape after the application had been submitted to building control. The cause of much of this conflict was the enormous magnet which was proposed.

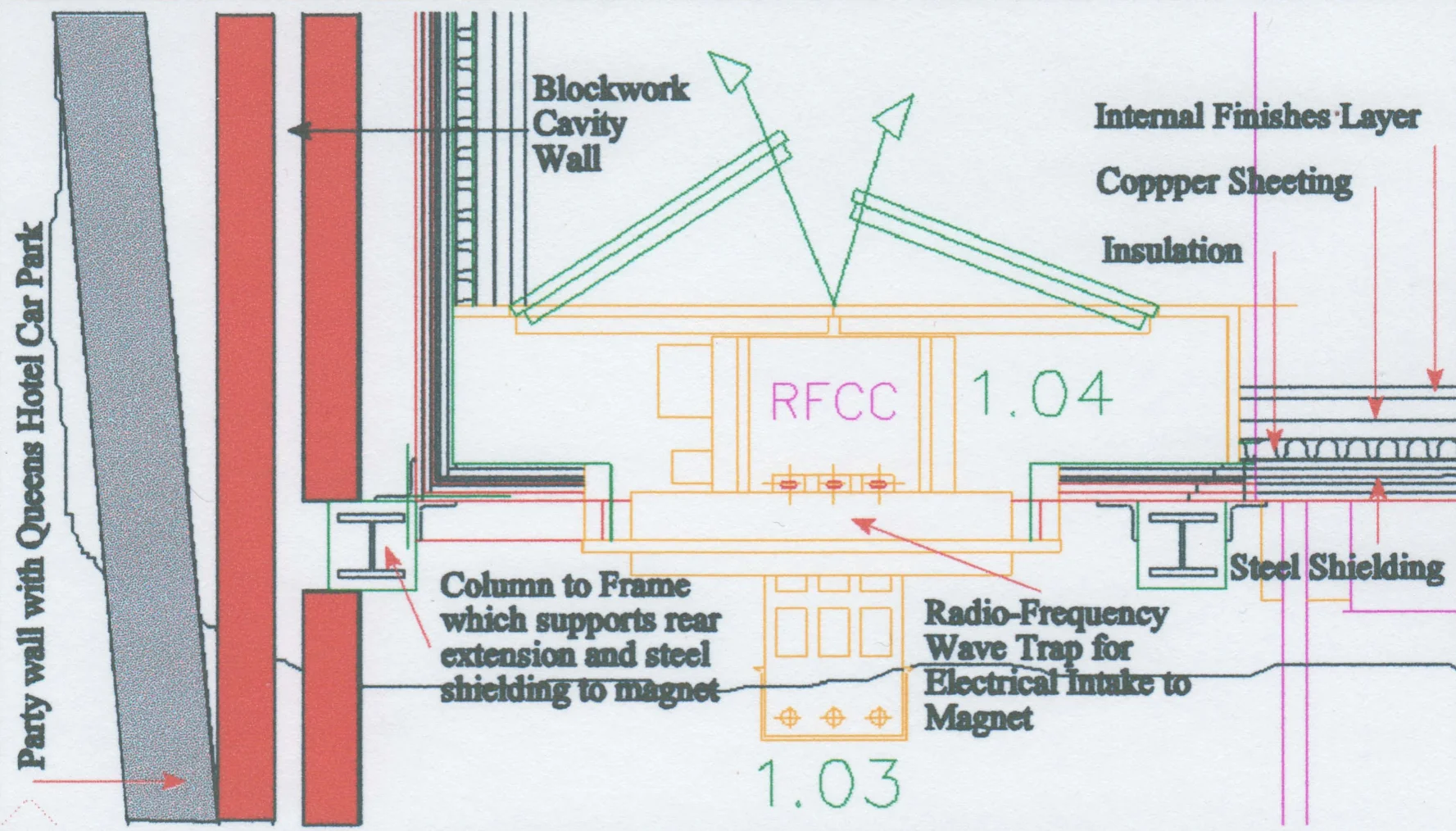

The MRI scanner functions independently to the PET scanner in the Lower Ground Floor of the Functional Imaging Laboratory. It makes no use of the Cyclotron to produce images of the brain. It does however require an enormous amount of plant to keep it functioning properly. It is sited in a radio frequency-free room to which must not allow rf in through the extract or supply ducts. Most important for human safety is the magnefs potentially harmful magnetic waves that must be contained within the safe confines of the room so the presence of patients wearing any ferrous implants such as pacemakers, pins or other medical engineering related implants may be kept clear of potentially life threatening circumstances. This shielding requirement for the magnet also is important to "blind" irs sensitivity to moving ferrous objects such as cars or trolleys outside the room. Therefore, the room has many layers which perform as finishes, radio frequency exclusion, anti magnetic steel shielding and associated structure to act as a skin which is constructed of many different materials both cast and fabricate<;i The construction cost of this part of the project rivalled the cost of the pet! cyclone bunker yet consisted of more complex construction solutions (compared to mass concrete). The examination room (where the magnet is placed) requires humidified air conditioning at the rate of one air change to the room every three minutes and the humidity level should not to exceed 70%. The magnet requires internal cooling and uses liquid helium that expands and vaporizes when heated. This process is continuously occurring when the magnet is functioning. Hence the mechanical ducting reqUirements of the room were further complicated by the recapturing of the helium vapour and transferring it to the nearby helium reliquification plant where it is re-cooled and stored for future use. This process takes place in a small room sewed by the adjacent large room to the south called the MRI Computer Room. It is in this room that the Magnefs electronic support takes place while most mechanical support comes from above the MRI suite in the ground floor plant room. The helium reliquification process is occasionally suspended by an event known as "quenching· when the magnet is overcooled and a discharge of freezing air and helium is ·sneezed· out of a flue which discharges into the atmosphere, causing a dangerously cold flurry of snow and ice which could cause bu.ll1s to human flesh and Is routed through the ground floor plant room to the open air above in much the same manner as a chimney or a flue. Both the electrical and mechanical ducts through the skin of the MRI were conducted through specially manufactured ·wave traps· which Siemens supplied to the contractor who successfully tendered to build the skin hereafter known as the RF Cabin. Siemens also specified the thickness of the steel (Iron) shielding which was required to be constructed of laminated sheets of .Smm thick transformer Iron to a maximum thickness of SOmm. This shield must not have been butte jointed because magnetic waves bulge through butte joints in the metal, all joints were staggered. The quality of the cuts in the metal had to be flush and could not be uneven especially where holes had to be cut for the wave traps to function property. These stainless steel castings formed tunnels in the wall of the rf cabin. In the same way that a car radio no longer receives in a tunnel, the patient on the gantry of the MRI must not be able to listen to the BBC. Naturally the interior flf-out of the MRI suite precluded any use of ferrous metal- even In the light bulbs specified for the room. The manufacturer provided free of charge his catalogue of speciaHy nonferrous fixtures, fittings, computer monitors, and furniture that would not be ma netically attracted to the scanner.

Detail through MRI Radio Frequency cabin showing wave trap for service ingress! egress

There are many more requirements that the MRI imposed on the project and all of the consultants were occupied fulfilling them to the best of their ability, not least of all the services engineers who faced changing requirements and the

onerous multitude of requirements. Nevertheless, the effect of the planning of the MRI Suite upon the building regulations application and the process of tel)dering the MRI Suite shall remain the primary focus of this section. In fact, there are no building regulations regarding the level of magnetic waves in the means of escape route. There are regulations regarding the construction of hospitals called the Hospital Technical Memorandum which determines special requirements for hospitals and there is no mention of precautions to be taken in the case of magnetic waves. It was then the duty of the architects and upon the manufacturer to assure the users of the building of their safety. With this in view, the manufacturer issued to the architect a complex specification that described the performance of the magnet which is simplified by the following diagram:

Means of Escape from the MRI Suite.

The architects knew that ultimately they could be held liable for any accident which might happen as a result of their planning of the building. They realized that the escape route traversed the magnetic field that bulged outside the open rt cabin doors when the magnet was on. Despite reassurances that the MRI power supply was cut in the event of a fire alarm and despite increasing the thick.Q.ess of the steel shielding around the magnet, they could not guarantee that a pacemaker-bearing visitor to the lab would be safe if escaping from the basement (not to mention inadvertently entering the area in normal use). Ultimately, signage prohibiting the entry of such a person to the premises of the basement would have to be displayed at all entry points. Smart card swipe security to all controlled areas of the facility were already an institution and the client signed off the general arrangement plans claiming that these issues were largely management issues. Siemens drawing which specified the thicknesses of pure iron shielding to contain harmful magnetic waves within the confines of the examination room. There also existed a means of escape path from the Queen's Hotel Casino to Queen's Square that ran directly behind the external wall of the MRI Suite. This presented the client with grave news from the manufacturer that a substantial thickness to the iron shield would be necessary to assure safety. This also presented planning problems when locating the magnet because any other alternative would have moved the magnet closer to the pet scanner. These two machines were mutually exclusive of one another In that the electronic processes within each interfered with the other. Therefore they had to be located as far apart from each other as possible and certainly no closer than a recommended distance of 30 metres. Compromises in safety and functionality had to be made because of the small size of the clienfs choice of site. It would be interesting to know how current safety legislation might have prevented this client from choosing this site for the building ... This is not to say that the size of the site was too small to prevent the architects from building a ·Iarge" building by building regulations standards. The highest level of accommodation was just under 22 metros above ground level, this should have prevented the requirement to have an alternative means of escape (provided there was lobbied access to the stairwell). The presence of a seminar room on the fourth floor with a capacity of 1 DO, persuaded the Fire Officer that an external stair would be required. The architects soon found that the Building Control Officer was keen to consider the building under the rules of The Hospital Technical Memorandum. This meant that the escape requirements from the building were much more stringent due to the Portion of Architect's Roofplan showing contorted Means of Escape which passed through building control. assumption that non-ambulant patients would be present and that they would not traverse many changes in level to escape from the building.

Therefore, under HTM, the external stair which served as an alternative means of escape had to discharge at ground level- not on a roof top as the architects were forced to propose. Efforts were made to comply with this requirement by extending the external stair down a well which would puncture the first floor roof and the ground floor down to the basement. Ultimately this was impractical due to water penetration and limited space. Appeals were made to the Bea to the effect that the lab was primarily a research establishment and that there would not likely be any non-ambulant patients which would have to escape from the upper floors which were dedicated to data analysis. Therefore an additional external stair was added to the final leg down to the rear courtyard of the Institute of Neurology which sprang from the parapet of the ground floor roof garden. (see roof plan) This entire rear extension of the building was originally planned as a load bearing structure to the steel framed main building. However, when the steel shield for the magnet developed into a massive shell of armor covering both the sides, undersides and top of the magnet, one architect had the idea of supporting both the shield and the rear extension with a steel frame. After consideration, this method proved to expedite the construction program and create synergy between trades according to the project manager, In fact, the steel frame proved to be a good check for the blockwork contractor when setting out his walls (although there were some discrepancies found in the setting out of the steel work). The steel shielding contractor designed his shield to be supported by the steel frame. The waterproofing contractor was able to proceed his trade under cover of roof although the blockwork was only partly complete. This synergy sometimes resulted in overcrowding on site and yet the tower crane was only available during the erection of the steel. This meant that valuable paletteloads of clockwork were craned into the site and made ready for loading out without an excessive labour force. After erection of the steelwork, the crane was removed and the population on site increased dramatically. The Tender interviews for the construction subcontract of the RF Cabin and the steel shielding were limited to two invitations partly because of the specialized nature of laminating 7000 sheets of iron into a precise magnetic wave proof construction. Premise Engineering Ltd. and Genesis Medical Engineering Ltd gave wildly varying tenders for the steel shielding. One tender came in at £90,000 and the other at £30,000. Little wonder why the Project Manager gave the contract to the lesser bidder. This bearing in mind

that the successful (and cheaper) tender came from a company that had recently been reformed after going into receivership. The project manager's requirement from all the subcontractors was a parent company guarantee (or a collateral warrantee) which would protect the client from sudden bankruptcy of a subcontractor. This, the successful tender company agreed to and qualified by a warrantee from irs ·parent company to commence construction of the RF Cabin. This company was not considered to have a sound method statement at the initial interview however. When quizzed as to the tools which they would use to cut low tolerance openings in the shielding, they replied with an Oxyacetylene cutter torch that was view by the architect as using a crude tool to perform a highly precise task consistently and repeatedly. They were later asked to revise their method statement for a second stage interview. Later, they returned to the second interview with a completely revised statement showing the use of computer guided laser cutting equipment and computerized jigs and pre-site assembly and installation. All fears allayed, they went on to win the contract and at the time of writing, they are about to commence their installation of the RF Cabin. Progress toward a fully coordinated mechanical & electrical scheme has been left to the subcontractors to complete as the services engineers became overloaded with revised Siemens requirements and changes in equipment specification. It is rumoured that the size of the magnet has increased and the magnetic power of the magnet has decreased in the "as built version". Now thatthe design team meetings are complete and the main fabric of the building is complete on site, information from the project manager is scant and architects involvement on site is not required ... only an occassional visit to the site.

Chapter 9: Conclusion to Case Study of A Functional Brain Imaging Laboratory

"No person who is not a great sculptor or painter can be an architect. If he is not a sculptor or a painter, he can only be a builder"- or so said John Ruskin in his Lectures on Architecture and painting. What would he have thought of the phenomenon of the Project Manager? The difference between a builder and an architect is one of circumstance. The builder is in the circumstance of solving problems with right or wrong solutions to the execution of a set of building plans. The Architect is in the position of solving problems with only good 0 bad solutions throughout the process of preparing those plans. If he does not intend to build the building himself, then he must expect others to carry out his plans. This is a great expectation, and a great risk if the architect is aloof to the construction phase of the project. The solution for the architect must be that he should excel and retain control over the construction solutions and the building costs in order to assure himself of his plan's execution. If he loses or delegates control over these to others, then he risks losing his authority to implement his design solutions and ultimately control over the design of the building. The complex problems of land use, town planning and architectural registration are the architecfs expertise through long years of training. These are possibly lost to the expedient issues of cost, buildability, and program of construction. The neglect of the the sum of all of these issues often results in poorly designed buildings, not architecture worth having in our cities. . The trend toward project management is the thin end of the wedge. Examination of the Project Manager's contract demonstrates the harsh reality that "the design and construction manager" is in a contractual position to change the architecfs design without neccessarily taking on the liability of amending the design to suit his 0Nn goals (and in some cases, Quietly rejecting the waterproofing strategy with only a manufacturer's warrantee to console the architects indemnity policy maker). Agents of the Project Manager have admitted to me on site that they have in some cases used their contractual position to -"change the design" where they deemed it necessary due to inappropriate solutions proposed by the architect. From the Project Manager's point of view, the architecfs role is still a necessary evil. The Planning Control Process is still an obstacle to the wanton developments of the uneducated profiteer as well as the esoteric academic. For architects like the Devereux Partnership, whose proposals are rarely opposed by the planners, the dictates of the planning officer are the only authority which the architect has to wield against expedience. In one case the Project Manager proposed that the copper roof of the building should be respecified as a glass fibre roof which could have been painted the same colour as the oxidized copper in order to save ten thousand pounds. The only prevention to this proposal W9S the objection by the planners in Camden and the activists in The · Bloomsbury Conservation Group. The architecfs objection to this did not factor in to the project manager's equation ... expedience + reduced cost=profit + reputation. Time will tell if the end result of the process of diversifying the roles of quantity sUNeying, design and site inspection will eventually lead to the consolidating of power to the super contractor who may eventually control all of the aspects of building. In this scenario, what controls will be necessary to insure that the building will be usable? In many cases, cheap buildings now result in lost profit to the users as a consequence of poor design. A study performed over many years by DEGW concluded that a corporate client is likely to save money in the long run by increasing the quality of design and specification of his building in order to increase the productMty of it's inhabitants. However, short term profit provides incentive for developers to ignore these findings.

With the rise of the project manager in the building industry, he approached the client purporting to complete projects more quickly and more cost efficiently than an architect. The architect's traditional role is restricted to design & drawing & liability without the control and authority which was necessary to implement the drawings. The project manager proposes to the client that he should compliment the design team with his management experience to take control (but. not the responsibility for) the specification and the construction process- in order to control costs. The Project Manager also requires a type of design veto in order to control costs and he exercises that veto through the client. Once this process is complete and the budget is firmly set, trade packages tendered, contractors appointed, the construction of the building commences along a programme path which the project manager has defined in order to demonstrate to the client that his raison d'etre is justified. In fact, from the experience on the Functional Brain Imaging Laboratory, the project manager brought with him additional benefits for the client (and indeed the rest of the project team) in the form of a highly trained and experienced person with a civil engineering background and a good team leader. Unfortunately, at times, the presence of such a role has lead to fractious relations between disciplines and a uncoordinated, over-budget and overdue scheme for the client.

The MRI Suite- A Group of six rooms that together with its equipment constitute about five million GBP.

The MRI scanner functions independently to the PET scanner in the Lower Ground Floor of the Functional Imaging Laboratory. It makes no use of the Cyclotron to produce images of the brain. It does however require an enormous amount of plant to keep it functioning properly. It is sited in a radio frequency-free room to which must not allow "rf" in through the extract or supply ducts. Most important for human safety is the magnets potentially harmful magnetic waves that must be contained within the safe confines of the room so the presence of patients wearing any ferrous implants such as pacemakers, pins or other medical engineering related implants may be kept clear of potentially life threatening circumstances caused by the magnetic attraction.

Lower Ground Floor- Neurological Equipment Intensive Level

No other section of the building suffered more conflicts of adjoining owner rights, means of escape, magneto-technical and constructional complications than in the two storey rear extention. This was especially true of the building regulations application where there were several revisions to the fire compartmentation and the route of escape after the application had been submitted to building control. The cause of much of this conflict was the enormous magnet which was proposed.

Ground Floor- Mechanical penthouse above rear extension/ Reception and public lobby at the front.

Programming usable space around a central external feature is a formal planning technique which worked well in this building's more public spaces on ground floor but also at basement level and at first floor level. The condtions around the tree pit on these other levels are shown above:

All being well with the strategic strength of the architectural concept, the omission of a mechanical & electrical philosophy from this concept leaves the building with a divisive landscape feature which enhances the conception by other building professionals that the architect is failing in his obligation to be practical toward other issues such as artificial ventilation and cibce standard luminaire selection. Nevertheless, there was little compromise on the principle of the tree pit. While it reduced in size dramatically from the feasibility study, it's location next to the garden wall meant that there was no way to bulkhead services along the wall without externalizing the ducts as in the Lloyds of London building In the City of London. It also blocked the passage of ducts in the ceiling between the control rooms so that additional ducts had to be introduced to deal with the diversion.

Other additional costs of the tree pit were the addition of three reinforced concrete retaining walls to contain soil for the tree. This increased the risk of water infiltration into the basement and additional waterproofing had to be introduced to tank a retaining wall condition. It also increased the amount of external wall area which had to be made weathertight. However, the services engineer required a location for a sump pump in order to pump all of the drainage from the basement. The tree pit was chosen as the location for this feature because the building regulations did not allow a foul drain to be serviced from inside the building (let alone a clinical healthcare building), and an external manhole was required. This left little room for root structure in the tree pit and the entire exercize of designing around the tree pit in order to make the building work seemed futile as a result.

First Floor- An extensive terrace to the outdoors with an inverted membrane, offices for primary investigators are naturally lit.

Second Floor General Arrangement Plan

Third Floor General Arrangement Plan

Fourth Floor General Arrangement Plan

Fifth Floor General Arrangement Plan

MRI Quench Tube-

The exit of the exhaust pipe must be protected against rain and snow and against all kinds of animals. Wind driven debris must not find it's way into the duct. Additionally, quench tube end must be kept free so that evaporation is ensured. The free cross section of the mesh wire which permits unrestricted flow must be so dimensioned such that it is at least 2 times the cross section of the quench pipe.

Detail through MRI Radio Frequency cabin showing wave trap for service ingress/ egress.

The mechanical ducting reqUirements of the room were further complicated by the recapturing of the helium vapour and transferring it to the nearby helium reliquification plant where it is re-cooled and stored for future use. This process takes place in a small room sewed by the adjacent large room to the south called the MRI Computer Room. It is in this room that the Magnefs electronic support takes place while most.

Means of Escape from the MRI Suite.

The architects knew that ultimately they could be held liable for any accident which might happen as a result of their planning of the building. They realized that the escape route traversed the magnetic field that bulged outside the open rf cabin doors when the magnet was on. Despite reassurances that the MRI power supply was cut in the event of a fire alarm and despite increasing the thick.Q.ess of the steel shielding around the magnet, they could not guarantee that a pacemaker-bearing visitor to the lab would be safe if escaping from the basement (not to mention inadvertently entering the area in normal use). Ultimately, signage prohibiting the entry of such a person to the premises of the basement would have to be displayed at all entry points. Smart card swipe security to all controlled areas of the facility were already an institution and the client signed off the general arrangement plans claiming that these issues were largely management issues.

Siemens drawing which specified the thicknesses of pure iron shielding to contain harmfull magnetic waves within the confines of the examination room.

Portion of Architect's Roofplan showing contorted Means of Escape which passed through building control.

Progress photo showing building frame completion and location of the infamous tree pit.

Construction progress photo showing escape stair.

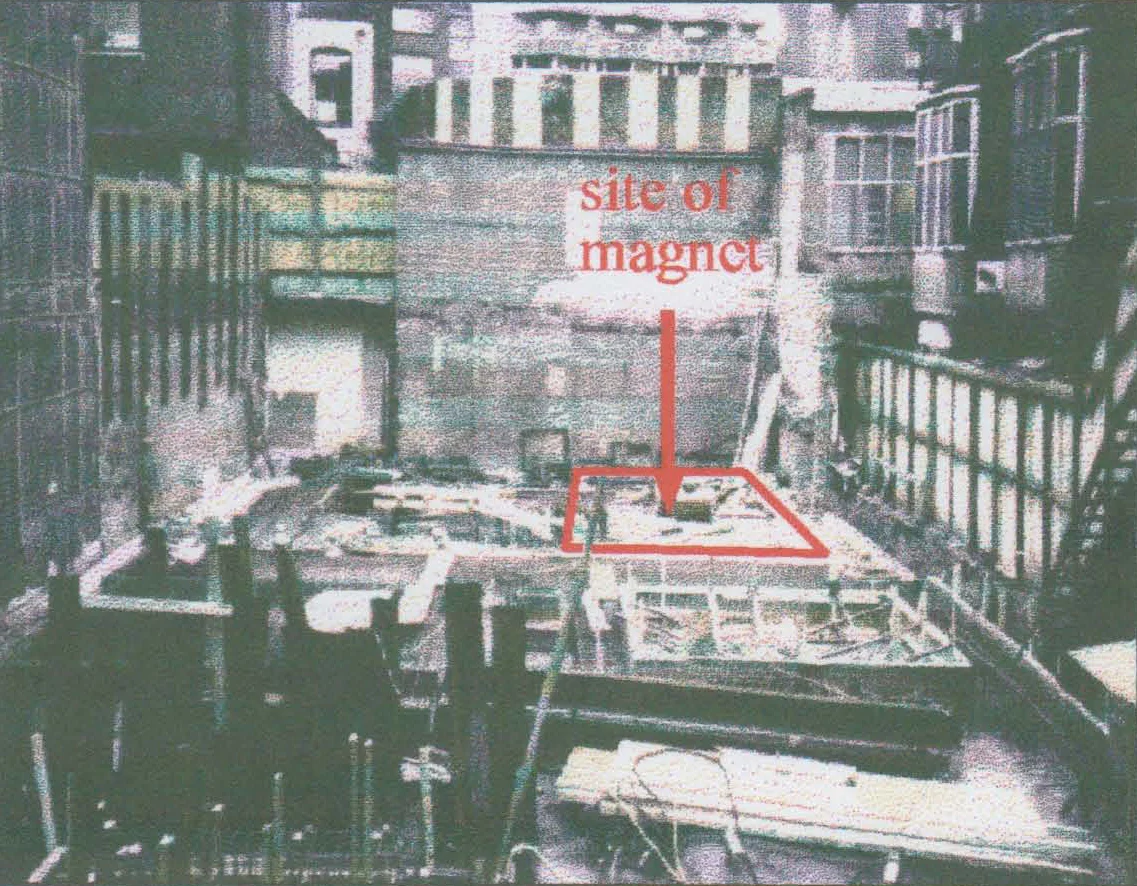

Early photo showing pedestal tie down to slab for MRI scanner.

Site photo during early ground works package showing site MRI scanner toward rear of construction area...

Cut-away view of the Radio Frequency Cabin

The Tender interviews for the construction subcontract of the RF Cabin and the steel shielding were limited to two invitations partly because of the specialized nature of laminating 7000 sheets of iron into a precise magnetic wave proof construction. Premise Engineering Ltd. and Genesis Medical Engineering Ltd gave wildly varying tenders for the steel shielding. One tender came in at £90,000 and the other at £30,000. Little wonder why the Project Manager gave the contract to the lesser bidder. This bearing in mind that the successful (and cheaper) tender came from a company that had recently been reformed after going into receivership. The project manager's requirement from all the subcontractors was a parent company guarantee (or a collateral warrantee) which would protect the client from sudden bankruptcy of a subcontractor. This, the successful tender company agreed to and qualified by a warrantee from irs ·parent company to commence construction of the RF Cabin.

Construction Progress- once the steel frame was complete, the site filled up with masonry and other material necessary to complete the construction was delivered to each trade.

Construction progress photo: congestion on site caused delays and coordination problems. The masonry contractor went bankrupt during the project.

Construction Progress Photo: Steel frame nearing completion.

Floating concrete on such a busy site was challenging, lowering the humidity of the spaces sufficiently to move equipment into position was another.

Construction Progress Photo- This view of the Ground Floor mechanical suite shows just how constricted the access for ducts from air handling equipment to the east was caused by the tree pit.

Construction Progress Photo: Excessive steel required to support the magnetic shield around the MRI Exam Room is visible in this photo.

Construction Progress Photo: Water-Proof Membrane as applied at complex juction in party-wall in MRI Examination Room