Neurological Research Institution associated with The Royal Institute of Neurology- Design Dev.

Architecture Firm: Devereux Partnership

Client: Royal Institute of Neurology

Site: Queen Square, London

Date of Project: 1993- 1995

Project Summary: This new building, sponsored by The Welcome Trust and The Royal Institute of Neurology- next-door-neighbor to the site of A Functional Brain Imaging Laboratory resulted in the demolition of St. John's House, an early twentieth century convent. In its place, a medical imaging lab for the study of episodic memory and other neurological conditions that utilized PET & MRI Scanning with an on-site Cyclotron (particle accelerator) and a Nuclear Medicine Lab (Blood Gas Analysis). The building probably should have been built in a green field site, away from the city- but for the critical relationship with the Royal Institute of Neurology (next door) the project was crammed into a footprint that was difficult to coordinate ground work, utilities and foundation structure and radiation protection.

John Millard's Role- I stayed with the project throughout all phases of design to construction when I joined the construction team and followed the project to construction completion as part of my RIBA Part III Case Study. There was one other (technical) architect working with me from design development to construction documents. We both reported to a principal in charge of the project.

Specific Role by John Millard: 1) Originate all CAD drawings, 2) Lead contact with Construction Management Team, 3) Coordinate Engineering Disciplines, 4) Communicate Equipment requirements from manufacturers to engineering team. 5) Produce all Schematic Phase Drawings for approval by Owner, 6) Produce all Design Development Phase Drawings for approval by Owner, 7) Produce all Construction Documentation Phase Drawings for approval by Owner/ CM.

During this phase of the project-

I had direct contact with the Neurological Scientists who were leading the research that would be pursued at the future building. The structural, mechanical, electrical and radiological engineers were also coordinated through me. Siemens, the medical imaging manufacturer, who made the cyclotron and the PET Scanner as well as the 2T MRI equipment used my desk as the point of contact for distribution of information related to the servicing and safety requirements for their equipment. I interfaced directly with the radiological safety officer on matters related to the cyclotron's standard operating procedures.

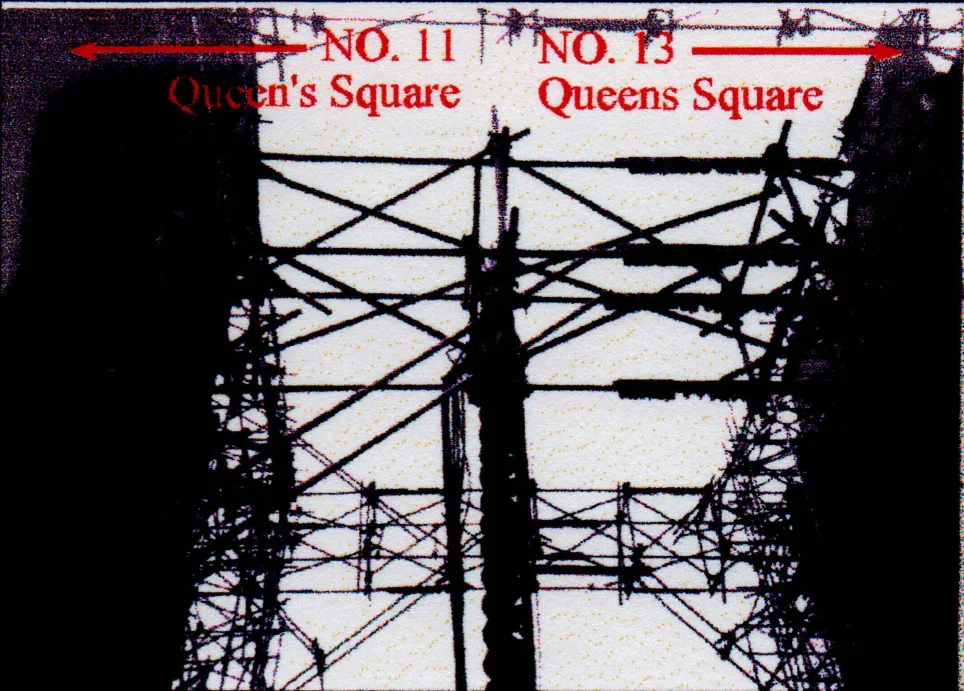

Chapter 4- Adjacent Properties

The adjacent property to the south is The Institute of Neurology (11 Queen's Square) from which all desirable neighborliness which a project architect could wish for from an adjacent property owner is available. In fact, the presence of the Institute next to the site is no coincidence according to the clienfs lead scientist who will use the Institute as a bully pulpit to advocate his discoveries and to accept willing subjects of research Into his building where they may be examined on a periodic basis. Where better to find a wealth of patlents? ... as stated clearly in the preceding press release by the architects. Never-the-less, at one point, just before ground breaking, the Institute of Neurology, allegedly prevented construction from proceeding by insisting that the charity responsible for funding the construction also purchase the site property and the existing building (which was scheduled for demolition). The trust agreed to pay for the site, and the building and the construction at the eleventh hour. Demolition was then allowed to proceed with the full cooperation of the Institute of Neurology. Their cooperation was fundamental especially as the Institute's rear premises were a necessary final destination for the alternative means of escape for the building under construction. Therefore a Right of Way had to be drawn up by the solicitors involved in the Project in order for the Architects scheme as designed to clear through building regulations. There also remained a number of structural modifications to No. 11 including a breach in the Party Wall and a Lobbied passage through accommodation in No.11 lower ground floor in order for the escape route from No.12 to the rear of No.11 to be possible from the lower ground floor of No.12. The architects scheme also depended on an external fire stair to be built on the adjacent property which would serve the upper floors of No.12 alternate means of escape. This stair, which descends seven metros from the ground floor roof terrace of No.1 2 to the rear yard of No. 11 remains undesigned and irs cost unknown. This is because of unsatisfactory proposals to the project manager by the architect in spite of repeated suggestions by the architect to negotiate a right of way for means of escape through No. 13 which already accommodates a means of escape route for the Queen's Hotel Casino. This route would not have nrequired any stair but the right of way but could have been as expensive If not more costly. This would have compounded the already difficult relationship with the adjacent property owners of No.13. They complained that the new construction would take light away from the fourth floor conservatory which they had recently completed and they threatened to withdraw their support for the project and requested compensation for their loss of light. The Party wall surveyor acting for the laboratory later discovered that the Conservatory was Illegally constructed on top of the party-wall. No action was taken in respect of this trespass so as to avoid project delay. The owners of this residential terrace immediately to the north of the site also owned the Queen's Hotel property that adjoins the site to the west. They did not object to the scheme at planning stage but appeared to be using the various inconveniences caused to them as opportunities to collect payment from the client as a result of the various agreements required by the client in order to proceed with the construction phase of the project. Issues arose which enabled the neighbors in No.13 to cause delay and increase the cost of various construction solutions. Issues such as oversailing rights by the tower crane and the nature of temporary works to the site which would support the adjacent properties. After the demolition of No. 12, the adjoining properties required temporary support. The owners of No.13 requested that flying shores which engaged their wall shound not use penetrative fixings. In return, they agreed to allow some use of their adjacent property to found scaffolding in order to greatly ease the construction of the rear extension to the new building where the magnet and the diverse selection of plans and computer rooms were located. Therefore a great deal of negotiation took place by the project managerand the party wall suNeyor in order to assure that the temporary works would not directly fix into the adjacent property (potentially damaging the party wall in the case of flying shores) and in the case of the scaffolds founding on their property, it was required that they did not obstruct the means of escape from the casino and they had to be a specialized form of scaffolding which cantilevered off of it'self inorder to reduce the number of low level obstructions. The conservatory issue is still a problem because it is Illegal, the Laboratory will have to transfer the structural support for that part of the wall away from the party wall, inboard of the boundary. Brickwork will have to be laid overhand due to the glass roof of the conservatory. These issues were constantly emerging throughout the design process and showed the architects that having an active project manager on board can liberate design professionals from the sometimes emotional and onerous conflicts with third party clients. As a result of the involvement of the project manager from the earliest phases of the project, the architects were able to concentrate on the pressing package programs which were set out by the project manager. It does appear that the delegation of these legal & contractural 'aspects of building projects creates other professional roles within the Industry in the same way that delegation of coo estimation of construction to quantity surveying profesionals. These roles have emerged to the benefit of the architect. It would be a great pity if the architect delegated so many of the roles which are required in designing a building that there was nothing left for the architect to do except act as a draughting bureau. Control over the specification of the structural build & finish of a building is increasingly influenced by the structural engineer. The management and supervision of construction on site seems to be going the way of the project manager. All that remains for the architect to do is act as the purveyor of aesthetic and programatic decisions to be instituted into the drawings. In the next section of this report, examination of the project manage(s contract with the various consultants and contractors involved will reveal if there is any need for the architect to visit the site after ground breaking in order to enforce the decisions which he has made.

Chapter 5- Why was an architect required to design a Functional Brain Imaging Laboratory?

The healthcare industry requires architects because of the specialized nature of the medical building brief. Such a brief includes highly detailed room data sheets which account for every fixture, Including specialized ironmongery, electrical and sanitary fittings as well as removable items such as waste bins and wheeled beds and couches. All these items must be scheduled In packages. Room elevations must accompany the packages detailing the location of each fitting according to the requirement of each healthcare professional who uses each room. This highly programmatic task is accomplished through painstaken work by draughtsmen and usually involves the use of computers. This is to cope with inevitable revisions to plans and elevations once they are heavily Iooded with every manner of hospital fitting and furnishing crucial to a successful patient ward. Such responsibility is unlikely to fall into the control of any other building professional except possibly the services engineer. Secondly, the appearance of a medical building is usually a major Issue to both the users of the building and the Inhabitants of the environment as well as the funding body. Medical buildings are often located in sensitive contexts. In this cqse, the Bloomsbury ConseNation Group were happier to submit a drawing prepared by themselves for the main elevation than they were to accept the solutions put forward by the designer. Nevertheless, the architects were allowed to design the inside the building according to the wants and needs of the users of the building. This exercise resulted in months of general arrangement development that tended to frustrate thetechnical needs of servicing the building. Unfortunately, the strategic idea behind the design of the building had little participation by the services engineers to prevent the afore-mentioned architectural features from obstructing the flow of ductwork. Notwithstanding, such features aided in the penetration of natural light into the basement and generally improved the quality of light and space in the lower three floors.

Secondly, the appearance of a medical building is usually a major Issue to both the users of the building and the Inhabitants of the environment as well as the funding body. Medical buildings are often located in sensitive contexts. In this cqse, the Bloomsbury ConseNation Group were happier to submit a drawing prepared by themselves for the main elevation than they were to accept the solutions put forward by the designer. Nevertheless, the architects were allowed to design the inside the building according to the wants and needs of the users of the building. This exercise resulted in months of general arrangement development that tended to frustrate the technical needs of servicing the building. Unfortunately, the strategic idea behind the design of the building had little participation by the services engineers to prevent the afore-mentioned architectural features from obstructing the flow of ductwork. Not withstanding, such features aided in the penetration of natural light into the basement and generally improved the quality of light and space in the lower three floors.

Thirdly, there was the need for someone to defend the client from the decay of quality through conflict of interest in the project. Namely, changes to certain construction applications (such as water proofing) to achieve a less expensive solution was in the architects opinion a false economy. The water-tightness of the building was the architecfs responsibility, and with £25M of medical scanning equipment In the basement, the architects took this responsibility seriOUsly. Nevertheless, the water proofing system specified to tank the basement was overruled by the project manager and the structural engineer because of a combination of cost and technical consIderatlons ... it had never been used by those consultants. The rejected system had been used by the architects on a £25M wing of the Notional Hospital of Neurosurgery on the opposite side of Queen's Square and British Standards called for cavity wall tanking in the situation such as the water table that we had on site. For reasons unknown to the author, a firm position on this issue was not taken by the architects when confronted by the two disciplines and a highly elastic waterproof membrane which could accommodate movement in the building was · used . to to,Qk the basement instead. (see minutes 1 Dec 1993 in appendix two calling for the architect to produce a performance specification for water-proofing) The project manager used the performance specification to invited tenders from waterproofing manufacturers who were able to provrde warrantees for their products performance to try to put the architecfs mind (and indemnity policy) at rest. However, upon closer examination of the manufacturer's warrantee, economic losses such as moisture penetration to the £25M worth of medical electronics in the basement were not covered. The architecfs role as quality controller on behalf of the client was frustrated by the Project Manager's contractual relationship with the subcontractor. In the contract nthe project manager takes on a role that is ill-defined in the contract but would nappear to give him the power to redesign aspects of the building to suit. In the first appendix of this report is a copy of the project manager's contract called "TRADE CONTRACT FOR USE IN CONNECTION WITH A PROJECT AT 12, QUEEN SQUARE, LONDON WC1" (hereafter known as "PMC"). This is a description of the relationship between the project manager and the various subcontractors who successfully tendered to build the respective packages. In the definitions of the contract on Page 1 is a definition of the word "Design Ie Construction Manager" which reads as follows:

"Design & Construction Manager" means Mace Limited whose principle place of business is 7 Plough Yard, London, EC2A 3LP, or any other person notified in writing by the Client to the Trade Contractor from time to time." -PMC Other references to "Design & Construction Manager" include: "3.6 The Design & Construction Manager may at any time instruct the Trade Contractor to comply with any such instruction without providing the said estimates or in the absence of agreement of the same, in which a fair and reasonable adjustment to the contract sum shall be made having regard to any applicable Schedule of Rates or Pricing Schedule. This is to describe how the trade contractor should comply in the event of a variation but according to the "Concise Encyclopaedia of Architectural Practice" by David Chappell and Ray CeciL ..

"A variation is any change in the work specified in the contract or the conditions under which it is to be carried out. Most forms of contract stipulate that no variation shall vitiate the contract and provide rules for valuing the variations. There are additional provisions within the JCT forms for recompensing the builder if the stated methods of valuation do not adequately compensate him. Notwithstanding the "no vitiation" clause, a variation can be of such a nature that it changes the scope of the contract. In such cases the instruction itself is invalid and is outside the architecfs authority." as in JCT Standard Form of Byildinp Contractl98Q Edition, hereafter known as "JCT 80"

"4-1 The Contractor shall comply with all instructions issued to him by the Architect in regard to any matter in respect of which the architect is expressly empowered by the Conditions to issue instruction; save that where such instruction is one requiring a Variation within the meaning of clause 13-1-2 the Contractor need not comply to the extent that he makes reasonable objection in writing to the Architect to such compliance" -JCT -80

Following these clauses within PMC & JCT 80 are corresponding clauses which entitle the client to "employ others" to perform the variation if the subcontractor has not compiled with the variation within five working days. What appears to be the difference between the two contracts is a fundamental expectation about the extent to which the design of the building is complete at the time of going to tender. In the case of the PMC the expectation is that the design is not complete at the time of tender and that the contractor should expect a culture of variation within the job. This is due to the fact that the packages of drawings that were issued for tender were correct at the time of issue. However, they were issued before the rest of the design packages were complete thus allowing the exercise of costing the construction to go on with perceived certainty. However, by the time construction begins, the consequences of completing other packages has not been registered by the subcontractor in his package of work before he has started or worse, after he has started. At this point, it may be possible that the design and specification of the consequent packages may suffer in order to control escalating costs.

In the case of the JCT 80, the expectation is that the architect is finished designing the building to the best of his knowledge because of the increased time which has been spent preparing an accurate record of the design. Indeed, the architects code of conduct requires that he do so ... " A registered person who intends to maintain his integrity so as to deserve the respect and confidence of all those for whom or with whom he may work in his capacity as an architect will assure himself that information given in connection with his services is in substance and presentation factual and relevant to the accession and neither misleading nor unfair to others ... " Sadly, if the construction industry is to be believed, this aspiration is seldom achieved by an architect (depending upon the project and upon the client).

The approach which the fast track project manager makes is entirely honest whereupon he admits that eventualities accur on projects where the design is intended to be complete, how much more on a project which is incomplete at the time of going to tender? If a builder is tendering for a fast track project then he will prepare himself to comply with directions from the design & construction manager in good faith that such eventualities will be recompensed on the basis of "any applicable Schedule of Rates or Pricing Schedule."

This is not how variations are dealt with on site however. Many variables are dealt with in a manner similar to JCT 1980. Subcontractors and the Site Agent for the Project manager rarely operate according to the Mace Contract with respect to variations, but rather work within a JCT80 culture. The variation is fi~st considered and priced by the subcontractor (and that price must be agreed with the Design & Construction Manager) before any work is carried out. If the price is not agreed, then a less costly construction detail is put forward by either party and agreed before any work is carried out. Not withstanding, this process can be expected to result in a more conventional detail (and possibly less elegant) than that which was originally the subject of the variation. Finally, the agreed variation is sent to the architect for approval that in the eyes of many is considered a rubber stamp exercise. The architect will normally concede provided that the variation (which may have been initiated by the design & construction manager) is coordinated with the rest of the scheme.

In the case of A Functional Imaging Laboratory, it has been observed that the interests of the subcontractor are best served by well coordinated information. They are also well served by programming the construction so that trades are not tripping over each others feet because of too many tasks being executed simultaneously by the design and construction manager. This problem is endemic on a fast track contract. At last notice the construction foreman was concerned enough about the problem that he alerted the health & safety inspector to make a spot inspection. This was in order that the project management company might be forced to comply with regulations regarding a number of safety issues ... as can be seen from a copy of the inspectors report shown here and below:

As a result of the inspection, the project management employed the scaffolders to provide proper gangways and to cable off unsafe areas. The bricklayers were paid to hold off while certain aspects of their access provisions were made good and their working area was cleared of all stored steelwork. Nevertheless, the following day the crane driver fell down the cage ladder and had to be hospitalized and a steel erector fell two storeys onto profiled metal decking and returned to his post bolting the steel frame together after a breather. It seems that safety standards are no guarantee against carelessness ...

In this analysis, funds from the project management to improve site access for operatives in the interest of safety were only forthcoming after their own construction manager called in the health and safety inspector for fear that someone might be seriously injured. If this is the level of commitment to site safety, what of the commitment to build quality and finish?

Chapter 6- Cost Over-runs

Early in the project, as the feasibility study was complete, the "in house" Q.S. on the Project Manager's side prepared initial costings which were underestimated. The revised costings at scheme design stage increased by as much as 30%. The increase warranted a "value engineering" inquiry/ workshop held by the project manager before going to tender. During this time, the events which had taken place since the planning consent were accounted for by each of the disciplines who experienced changes in their part of the design. The reputation of Architect Led Projects recieved a boost when the project management team which had come to grief over the unexpected cost overruns conceded that all of the increased costs of the scheme were justified. The client had to be notified that the project was suffering an overrun of at least 20% in cost, and the program had been set back by three months out of a twelve month period. The Welcome Trust responded by assigning a quantity surveyor from one of their own project teams to A Functional Brain Imaging Laboratory. This would normally not have happened on a Welcome project with a value less than 20M. The project management team then reported the history of the Project Budget directly to the Welcome quantity surveyor until all packages had been tendered. It is fortuitous for the Project Manager in this respect that the contract was not a fixed price contract. Were it not for the scientific urgency of the project it might well have been run under JCT 1980. The project had to be completed before competing scientists in other countries made breakthroughs in understanding & treating Parkinson's Disease. The project might well have been completed without a fast track project manager and a bespoke contract which allowed an early start on site with a stated but apparently flexible cost ceiling. One of the advantages of healthcare architecture is the well endowed nature of healthcare clientele.

The cost overruns began with a planning conditon that required the existing stone piano nobile be replaced. The cost of this was valued at £250,000. Additionally, there appeared to be a change of the escape requirements of the upper floors by the Building Control Officer and an external stair was later required due to the building's classification under "The Hospital Technical Memorandum" published by HMSO. This differed from the original classification under "~ Building Regulations" also published by HMSO. The addition of the external stair cost £---------. The building fell into a grey area of the regulations because it was primarily a research facility treated as an office by the building regulations in the upper four floors. The presence of examination rooms on the first floor and a highly populated seminar room on the fourth floor changed the b.c.o.'s view of the escape requirements after the initial co stings were calculated. Another cost overrun occurred when the equipment manufacturer Siemens PIc. later required the radiation shield to be increased in mass & complexity by a factor of four. This dramatically effected the underpinning works to adjacent properties by doubling the depth of the underpinnings to two metres. The frequency of piles was increased under the bunker and the ground works package and the piling contract suffered a £100,000.00 increase over initial costs.

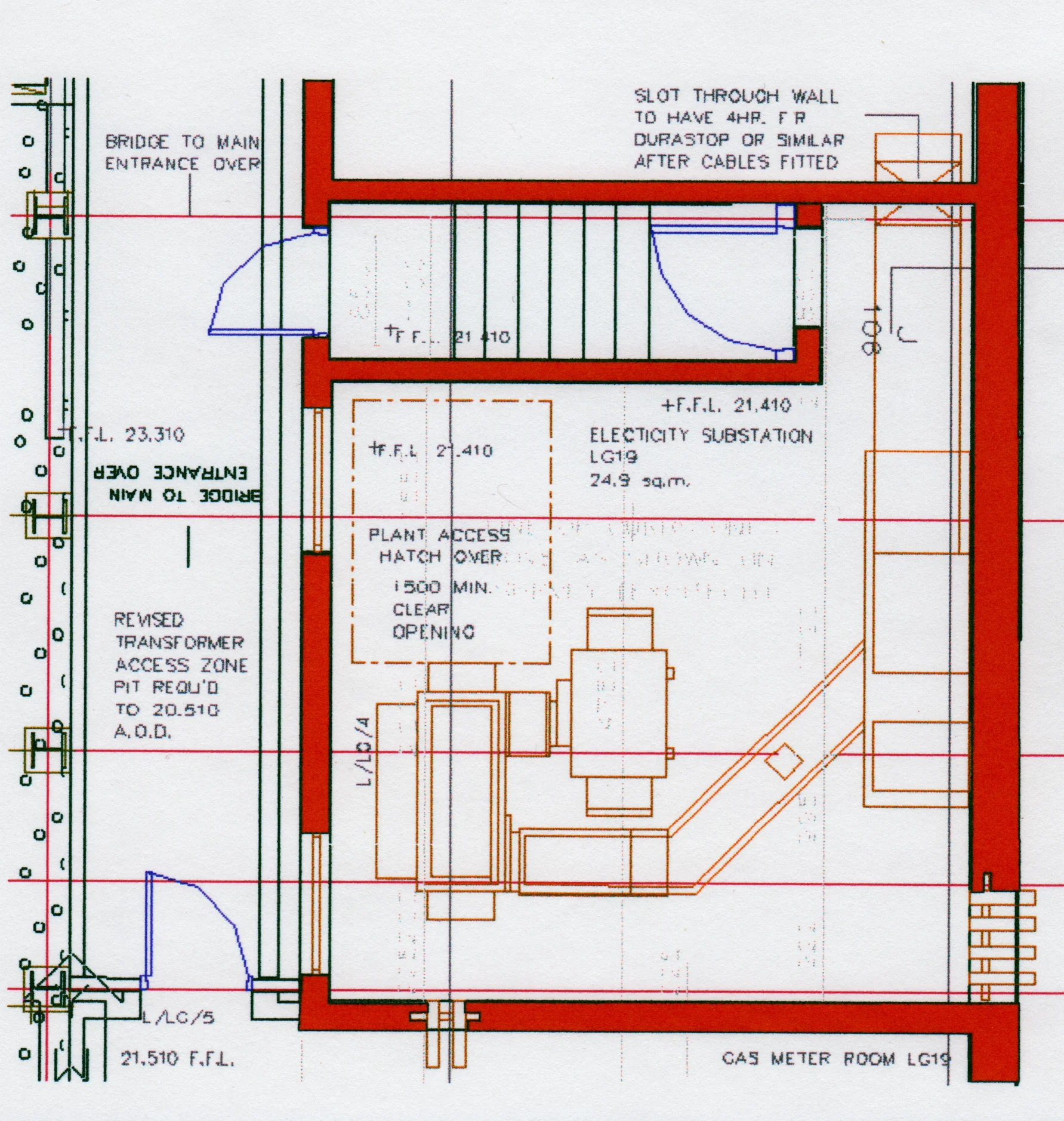

On the mechanical side, Siemens later specified that the radiation bunker mu~ be air conditioned. Until this time, it had not been thought that air should be supplied into the target area through eight foot thick steel reinforced concrete walls without increasing the risk of radiation escaping into the environs of the Laboratory. However, Siemens reassured us that tried and tested technology from air conditioning containment vessels on nuclear submarines was available. The additional cost of this is still not certain. A number of other factors effected the cost overuns of the project such as the inaccessibility of high voltage current in Queen's Square. Therefore, a private transformer substation had to be built under the pavement in explosion proof reinforced concrete vaults. Access to these vaults for delivery and installation of the transformers became a source of controversy during the design stage of the project. The services engineers differed with the architect who believed that transformer access should be through the roof via a service hatch in the pavement ... drawings were prepared and sent to L.E.B. directly. This access meant that underpavement services to the square might have to be disconnected for an unknown period of time requiring consents and additional cost. The services engineers were upset that L.E.B. had been contacted by the architect and a design for the vaults discussed without their approval because they wanted to access the vault with the transformer differently- by delivery through the light well and laterally loading the transformer in through the entrance of the vault. L.E.B. reviewed both schemes and preferred the architect's proposal. However, as construction evolves on the site, it would appear that the top of the vault has been cast without the opening for the hatch. It also appears that it may not be necessary to shut off the under-pavement services because of the tolerance that exists after excavation.

Chapter 7- Scheme Design Stage

It was apparent from the start of the F.l.l. Project, that much of the budget for the construction would be absorbed by cMI engineering works. The concrete radiation shield for the cyclotron proved to be the source of much expense tJnderground. From the Architecfs point of view, the funds for assuring procurement of quality materials, finishes and fabrication rested on insuring that the cMI works to the foundations were not over-designed, and that design of the radiation shield itself was not unduly conseNative without risking the general public's health and safety. This view was due to the constant budgetary reassessment which the project manager supervised. None of the project team members who were signed up with the project manager were qualified to calculate the thickness of mass concrete required by the radiation shield. The shield had to contain neutron and gamma radiation which the manufacturer calculated would be emitted by the cyclotron. The manufacturer (Siemens) made these calculations available to anyone who wished to design a shield for the cyclotron. In August 1993, Siemens suggested a shield which they accepted no responsibility for (shown below). Throughout the critical initial costing period, the entire project team were led to believe that the radiation shield posed no inordinate cost to the construction. It appeared that the shield was simply a reinforced concrete wall which would pose some additional cost but would not exceed wall thickness of 300mm. Therefore, the planning submission went in to the local authority (a Mnuclear-free" zone) with this quite inconspicuous profile having the room title on the drawings "oxygen generatorM. The Quantity SUNeyors at the Project Manage(s office estimated the cost of the room as an essentially insignificant sum and the engineers did not consider the room as a threat to their underpinning strategy. These assumptions later were proved to be ill-founded as the nuclear scientists at Siemens Pic slowly realized that they had drastically under-estimated the radiation output of the cyclotron in their design of the radiation shield.

The design "suggestion" for the shield was then passed on from Germany to the scientists in the U.S. In the transfer of information between continents, significant -details regarding the nature of the site were omitted. The fact that the site was a congested, sensitive, central London square with neighbouring grade 1 listed buildings flanking the site to the north and routh party walls was omitted and the Siemens scientists in the USA assumed that the site was a green-field site. This breakdown in communication should have been addressed by the project manager. The fact was that the people who were designing a 550 ton part of the building thought t~at the site was a green field. All communication with Siemens had to go through the project manager. The U.S. Scientists recalculated the neccessary thickness of concrete and produced aconservative bunker with six foot thick walls, ceiling and floor. This new bunker also contained a maze which compromised the workspace inside the bunker, around the cyclone itself in order to prevent the escape of gamma radiation. Initially, the defacto nature of events which surrounded this second design meant that the design team accepted it without question, and with much amazement. However, as the repercussions of the sheer mass of the bunker began to manifest, action to redesign the scheme and the bunker gathered momentum. By the end of November, the full implications were known. Complaints about the bunker's mass were telephoned through directly to Siemens as consultants broke ranks with the project manager's chain of command and communication. One architect telephoned the nuclear physicist responsible for designing the cyclotron and suggested a lithium based material of a soap-like density and consistency to replace the mass concrete in the bunker in order to reduce mass and thickness of the concrete walls. Her immediate response was why was the Project Manager not handling this aspect of the query and that the shield as proposed was only a suggestion and Siemens could not take any responsibility for the design. Consequently, as demanded by the project manager's drawing programme, this architect had to incorporate the suggested bunker (shown above) into the plans of the proposal and in doing so, moved the bunker vertically so that the roof of the bunker was equal to the finished floor level of the ground floor and eliminated the superfluous structure which

the engineers had spanned over the top of the bunker. This had the effect of reducing the depth of the 2000mm underpinnings to the party walls by 300mm. It soon became clear that any effort to reduce the depth of the bunker had the net effect of reducing the cost of the substructure. When it became impossible to move the bunker within the scheme any more, access ramps began to be shaved off of it, slightly reducing it's weight. Before long, the architect invited Ministry of Defense Subcontractors to design team meetings to lecture the design team on the merits of containment design in the confined space of a nuclear submarine. Their solution was to use the lithium based material called ·Premedex" which replaced approximately 1 . 5 cubic metres of concrete radiation protection with 1 cubic metre of Premedex protection for one tenth of the mass of concrete. Needless to say, at £3000.00/ metric ton of Premed ex, the Project Manager quickly calculated that the concrete was 50times cheaper than Premed ex even if the Premedex was only 10 times lighter. There were still savings to be made in the design of the steel tail-down cantilevered in-slab support system which the structural engineer used to increase the distance from the perimeter piles to the party wall edge. The detailing of this complex structure was already well advanced according to programme so that the ground works package could go to tender on schedule. The design of the steel members in the slab were proportional to the excessive loading which the concrete in the eastern end of the foundation posed due to the bunker. Savings could have been found in the excessive number of piles which had been planned to support the bunker. Nevertheless, the following letter to Siemens Pic.

Nevertheless, the following letter to Siemens Pic. had the effect of urging Siemens to redesign their suggested radiation shield.

After the SIemens package was Issued, and all requests to modify the radiation shield had been made by both the architects and the structural engineers, scheme design proceeded on the basis that there would be no modifications. WIthout Informing the design team, SIemens was quietly going about redesigning the US version of the shield at the Medical Engineering Headquarters at Ehrlangen. During this interlude, several packages were tendered wtthout benefit of changes which the engineers In Germany were preparing in the new shield design. The steel work package with the Tall-down system went out to tender, the groundworks package went out without moolfiCatlon,the piling package and the equipment package all became construction documents with out anyone aware that variations would have to be seNed to the successful

tenders In order to reduce the cost of the foundations. The increased costs which had accrued as a result of the post feasibility changes to the radiation shield and the stonework retention were beginning to worry the client bOOy and a special QS was appointed by the Welcome Trust to help rationalize the Increases which were being reported to the Trust on a monthly basis. The effect of this was a series of Project Management led "value engineering workshops· which resulted In improved understanding of the crisis by all parties. The architects view of the project became one of ·status quo· where the usual cost overruns experienced by architects on building projects were now being experienced by the project manager. These cost overruns were noN being experienced by the project manager partly because of the fragmented command and communication structure of the project. The severance of the architect from the client and employment by the Project Manager meant that all of the cllenfs Instructions to the architect, all of the perceived Interests of the client and all of the Interests of the architecture had to be filtered through the Project Manager. In the case of this project, the cMI engineering background of the Project Manager assured success and quality to the heavy works, but a uncoordinated relationship between each of the other diSCiplines Including the equipment manufacturer. This incoordination is one source of cost, the delay and the lack of cooperation between the services engineers and the rest of the team Is another. Architect led teams also have this element of malfunction but the addition of yet another discipline seems only to exacerbate the problem. When the SIemens scientists in Ehrlangen had completed their calculations for the new radiation shield they called a meeting at their UK headquarters In Bracknell. They still had not announced the new radiation shield. All of the consultants and the project manager were present at the meeting. They announced that they had redesigned the radiation shield using liquid paraffin as the hydrogen rich and economic gamma ray absorber which would reduce the amount of concrete In the bunker. this propa;al was greeted with some surprise by all In attendance because of the combustble nature of liquid paraffin which they proposed to fill large cavities in the concrete walls and ceiling. Nevertheless, they were able to Increase the amount of space where there was once mass concrete. According to Siemens, the safety of the cyclone operator was jeopardized by the cramped conditions around the machine Itself. If the operator collapsed while the door to the machine was open then it would be Impossible to reach the Injured party without causing further Injury- a reason (possibly the only reason) which none of the consultants had considered for redesigning the shield.

Search for an alternative material to paraffin began immediately. It was suspected that The Fire OffIcer and the Building Control Officer might object to the use of a flammable material as radiation insulation. It's encasement within the concrete also worried the project team because of the explosive potential of the detail suggested by Siemens PIc (rome thought the Project Manager should remind them of the impending D Day Commemoration) ... The consultants and the project manager ruled out ·PremedeX- because of It's high cost. Enquiries to British Nuclear Fuels and Sellafield turned up a new material which was inexpensive and eaS{ to install. It was Boronated Plastic and It shipped In 25mm thick sheets. Calculations by the manufacturer determined that It was sufficient to replace liquid paraffin, furthermore, It could be applied to the Inside of the mass concrete as a lining. This meant that no cavities would have to be cast into the concrete and the Inside of the bunker would have a handrome finish of plastic sheen with multicoloured speckles of boron making it the most fashionable cyclotron enclosure in the world. This is not to say that construction of the bunker would be eaS{. As It happens, the ground works package which the bunker fell into should have been complete some six weeks ago and the package is bound to suffer further delay as there remain a number of unfinished elements such as the r.C. upstand parapets and the r.c. retaining wall around the tree pit. As to the additional cost of this package due to the bunker, It should be ~Id that the architects spearheaded the effort to assure a rigorous design for the bunker so that the interests of the client were best served In terms of his brief and use of the ~Iotron as well as the best value for money. Unfortunately, as has already been ~id, the over-represented cMI engineering disciplines on the Design Team resulted in addressing the problem with over-deslgned solutions rather than lateral thinking and consideration of how the other packages might suffer financially from reinforcing an over-piied raft with 254x254mm U.C. sections.

After the SIemens package was Issued, and all requests to modify the radiation shield had been made by both the architects and the structural engineers, scheme design proceeded on the basis that there would be no modifications. WIthout Informing the design team, SIemens was quietly going about redesigning the US version of the shield at the Medical Engineering Headquarters at Ehrlangen. During this interlude, several packages were tendered wtthout benefit of changes which the engineers In Germany were preparing in the new shield design. The steel work package with the Tall-down system went out to tender, the groundworks package went out without moolfiCatlon, the piling package and the equipment package all became construction documents with out anyone aware that variations would have to be seNed to the successful tenders In order to reduce the cost of the foundations.

The increased costs which had accrued as a result of the post feasibility changes to the radiation shield and the stonework retention were beginning to worry the client bOOy and a special QS was appointed by the Welcome Trust to help rationalize the Increases which were being reported to the Trust on a monthly basis. The effect of this was a series of Project Management led "value engineering workshops· which resulted In improved understanding of the crisis by all parties. The architects view of the project became one of ·status quo· where the usual cost overruns experienced by architects on building projects were now being experienced by the project manager.

These cost overruns were now being experienced by the project manager partly because of the fragmented command and communication structure of the project. The severance of the architect from the client and employment by the Project Manager meant that all of the cllenfs Instructions to the architect, all of the perceived Interests of the client and all of the Interests of the architecture had to be filtered through the Project Manager. In the case of this project, the cMI engineering background of the Project Manager assured success and quality to the heavy works, but a uncoordinated relationship between each of the other diSCiplines Including the equipment manufacturer. This incoordination is one source of cost, the delay and the lack of cooperation between the services engineers and the rest of the team Is another. Architect led teams also have this element of malfunction but the addition of yet another discipline seems only to exacerbate the problem.

When the SIemens scientists in Ehrlangen had completed their calculations for the new radiation shield they called a meeting at their UK headquarters In Bracknell. They still had not announced the new radiation shield. All of the consultants and the project manager were present at the meeting. They announced that they had redesigned the radiation shield using liquid paraffin as the hydrogen rich and economic gamma ray absorber which would reduce the amount of concrete In the bunker. this propa;al was greeted with some surprise by all In attendance because of the combustble nature of liquid paraffin which they prq:>OSed to fill large cavities in the concrete walls and ceiling. Nevertheless, they were able to Increase the amount of space where there was once mass concrete. According to Siemens, the safety of the cyclone operator was jeopardized by the cramped conditions around the machine Itself. If the operator collapsed while the door to the machine was open then it would be Impossible to reach the Injured party without causing further Injury- a reason (possibly the only reason) which none of the consultants had considered for redesigning the shield.

Search for an alternative material to paraffin began immediately. It was suspected that The Fire OffIcer and the Building Control Officer might object to the use of a flammable material as radiation insulation. It's encasement within the concrete also worried the project team because of the explosive potential of the detail suggested by Siemens PIc (rome thought the Project Manager should remind them of the impending D Day Commemoration) ... The consultants and the project manager ruled out ·PremedeX- because of It's high cost. Enquiries to British Nuclear Fuels and Sellafield turned up a new material which was inexpensive and eaS{ to install. It was

Boronated Plastic and It shipped In 25mm thick sheets. Calculations by the manufacturer determined that It was sufficient to replace liquid paraffin, furthermore, It could be applied to the Inside of the mass concrete as a lining. This meant that no cavities would have to be cast into the concrete and the Inside of the bunker would have a handrome finish of plastic sheen with multicoloured speckles of boron making it the most fashionable cyclotron enclosure in the world. This is not to say that construction of the bunker would be eaS{. As It happens, the ground works package which the bunker fell into should have been complete some six weeks ago and the package is bound to suffer further delay as there remain a number of unfinished elements such as the r.C. upstand parapets and the r.c. retaining wall around the tree pit. As to the additional cost of this package due to the bunker, It should be ~Id that the architects spearheaded the effort to assure a rigorous design for the bunker so that the interests of the client were best served In terms of his brief and use of the ~Iotron as well as the best value for money. Unfortunately, as has already been said, the over-represented engineering disciplines on the Design Team resulted in addressing the problem with over-deslgned solutions rather than lateral thinking and consideration of how the other packages might suffer financially from reinforcing an over-piied raft with 254x254mm U.C. sections.

This problem was compounded by a reluctance by the Project Manager to criticize Siemens Pic., as the greater interests of Mace Ltd. would have been served by compliance and acquiescence rather than objective consideration of the undertaking which the client had set out to accomplish. Not one consultant on the design team would differ with the view that a greenfield site In Hounslow or Greenford would serve the project by haMng the cost of the ground works package, the cost of land, and eliminate the retention of the Portland Stone as well as greatly simplifying construction access and method. It is not within the scope of this project to detail the construction methods used or how they were complicated, but the following series of photos conveys some of the access difficulties as well as the intensity of construction which was required of this 600 square meter site:

Preparing the site for a 550 ton concrete bunker meant intensive piling under the bunker and frequently along grid lines. One concern which the structural engineer had was that the excessively weighted east end of the building would result in negative loading at the west end. This required use of the weight of the external walls to be linked into the substructure using cantilevered taildown beams which would cantilever the external walls off of piles located along the perimeter of the site. This meant that piles would have to be drilled exceedingly close to the party walls. Access to these areas was Impossible with a conventional pile driver which required great head height. The temporary works impeded the movement of such plant and required the use of gravity drop piling which is time consuming and costly.

Ultimately, the client is responsible for the choice of the site. The structural engineers designed a complex -belt & braces- foundation system and delivered a viable temporary works package and program which assured all involved (especially the adjoining owners) that the rights to support were under control and that the construction of the building could proceed without to many hindrances as a result. The final outcome is yet to be known since the building is only half complete by this stage but thus far, every assurance has been taken by the design team and at great expense to the client ...

Sketch of the now demolished St. John's House showing basic fenestration and massing.

Concept sketch of the proposed replacement building.

Sketch study showing subdivision of facade by Peter Hughes.

Sketch study showing subdivision of facade by Peter Hughes.

Photo Montage showing proposed party wall abutment profile on 11 Queen Square.

Photo Panorama showing main east section of steel frame during construction.

Photo Panorama showing west section of steel frame during construction.

This glazed enclosure was constructed without construction permits and the owner claimed illegitimate rights of light requirements.

Roof Plan of A Functional Imaging Laboratory

A stepped section in the building forms a non-negotiable chasm in the relationship between main building and the services extension where most of the heavy plant is located.

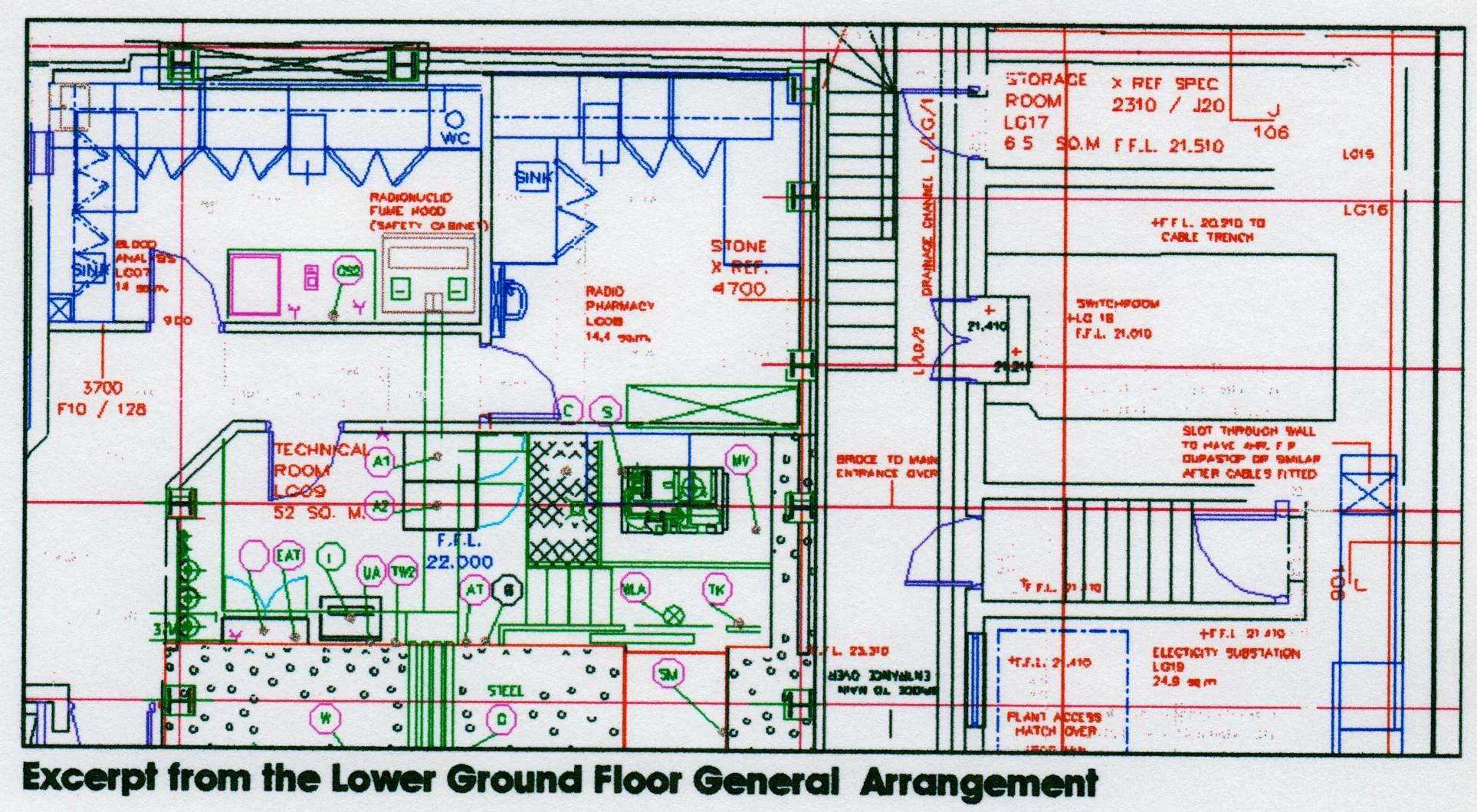

Plan of Radio-Isotope Production Area- Patients breathe radiated oxygen prior to PET Exam

An excerpt from the lower ground floor general arrangement indicates a need for some coordinating role between the architect, manufacturer of the equipment, the structural engineer, the mechanical and electrical engineer and the client- all of whom issue information independent of one another. ShoUld the architect perform this role or should the project manager? Is the detailed information produced by the architect in an information vaccuum unless he is performing this role? Should the architect also perform the role of a project manager in order to be effective in coordinating information? Or has a new role evolved on the complex project, one which combines the authority of both roles with a design & construction managing role which carries through the drawing office on to the construction site with full contractural control over all construction?

Unforeseen cost- there was not sufficient electric power infrastructure serving the property at Queen Square.

Unforeseen Cost: Concrete Foundations

The 36 piled foundations required to support the 500 ton cyclone bunker (also an unforeseen cost) tipped the budget over by an order of magnitude largely because of the fact that at the time the project was designed, there were only four PET scanners in the world.

Early design of the radiation maze...inadequate for the amount of radiation emitted by the Cyclone 3 particle accelerator.

Evolution of the design of the Cyclone 3 Radiation Maze was disruptive to the mechanical and electrical pathways into the building.

Cost Estimation- Concrete Foundations were a clear offender in cost control.

Photo of costly tail down beams.

Final design of the radiation maze included cavities in the concrete that were filled with propane, a hydrogen-rich substance that stops gamma radiation.

Overhead scaffolding (flying shores) obstructed piling equipment access to excavate the holes in the ground for the piers.

Drop piling is an expensive alternative to a drilling rig for excavating piers.

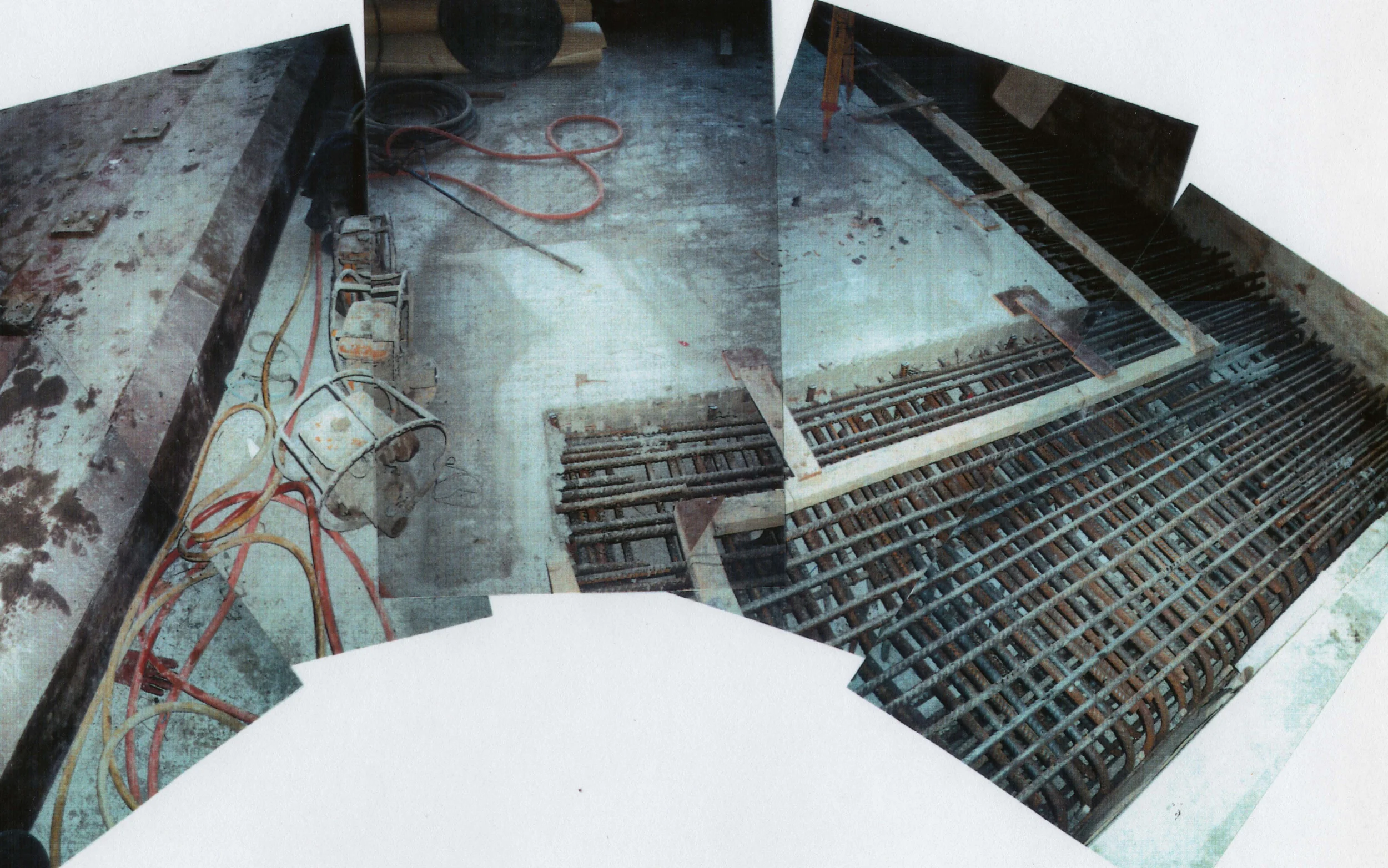

Photo 1 of reinforcing bar and concrete for the radiation shield.

Photo 2 of reinforcing bar and concrete for the radiation shield.

Photo 3 of reinforcing bar and concrete for the radiation shield.

Photo 4 of reinforcing bar and concrete for the radiation shield.

Photo 5 of reinforcing bar and concrete for the radiation shield.

Photo 6 of reinforcing bar and concrete for the radiation shield.

Photo 7 of reinforcing bar and concrete for the radiation shield.

Photo 8 of reinforcing bar and concrete for the radiation shield.

Photo 9 of reinforcing bar and concrete for the radiation shield.

Photo 10 of concrete for the radiation shield.