Your Custom Text Here

Project Data

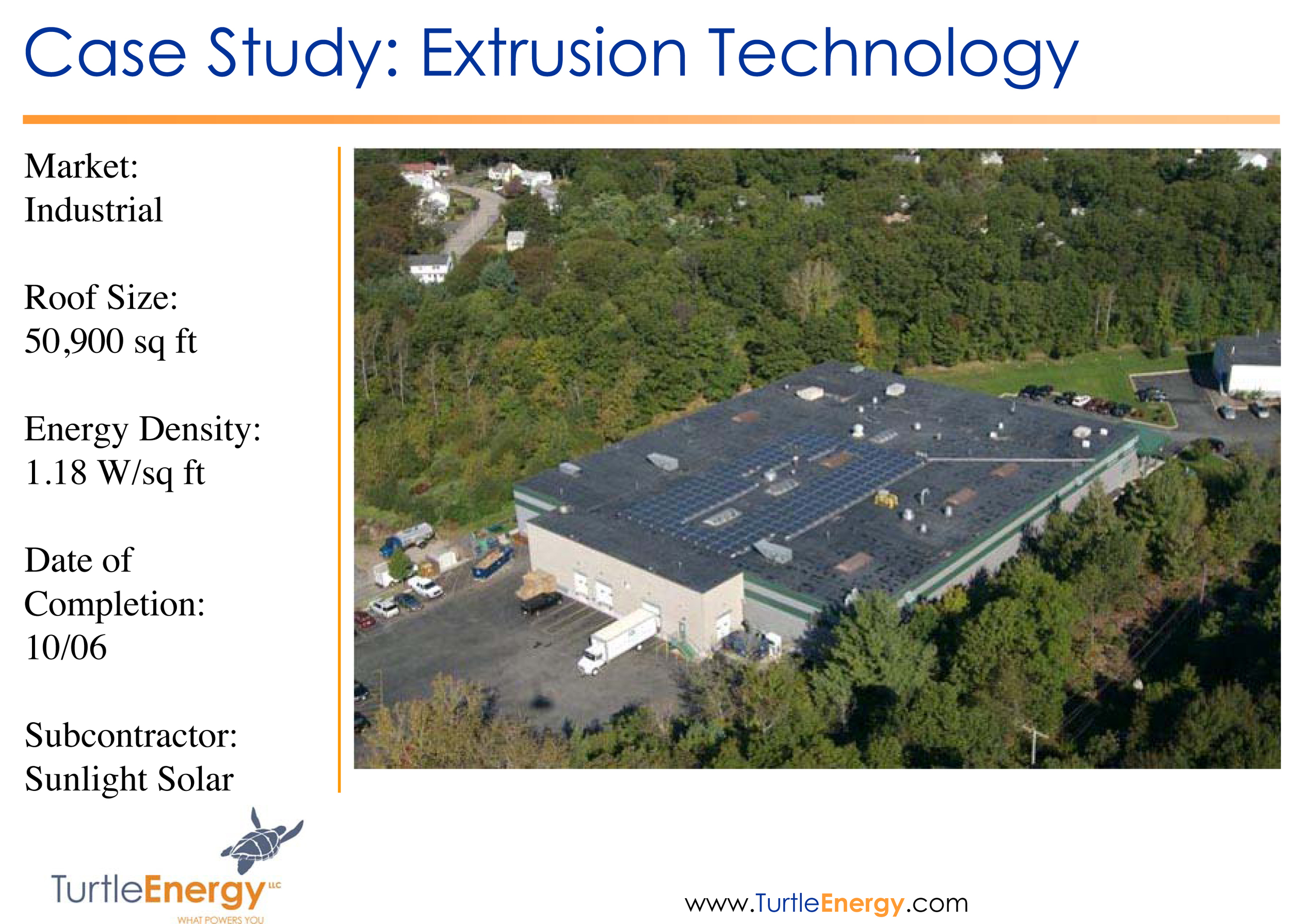

End-User: Extrusion Technology

Installer: Sunlight Solar Energy

Location: 80 Trim Way, Randolph, MA 02368.

Date of install: June 2006 – November 2006

Size of system in kW: 60kW

Energy produced since installation

Special Challenges Met: 1) Building roof structure had to be reinforced to withstand the weight of the PV system. 2) Wind loading for the location was 110 mph.

Project Brief

Extrusion Technology is a custom specialty extrusion company, where blocks of metal are taken and forced through a die to form it into the required shape. Turtle Energy designed a Photovoltaic system to be installed on the building. The installer for the project was Sunlight Solar Energy. Due to their location in Randolph, MA Turtle Energy suggested that they use the MA made product from Schott so that they could qualify far a larger rebate from the State.

Turtle Energy undertook a detailed analysis of the site. This analysis was comprised of the following steps and implementation.

Shading Analysis

Optimal System Design and Concept Planning

Industrial Design of the Components of the System

Multi-Disciplinary Coordination with Architects, Structural Engineers, Electrical Engineers, and Construction Management.

The module and mounting hardware manufacturer provided wind analysis by a civil engineer. This analysis showed that the site required planning for 110mph wind loading consequently ballast had to be added to the Schott FS system. Gale Associates structural engineers advised that the roof structure be reinforced to ensure that it would support the PV system; this work had to be done prior to installation of the PV array.

The project commenced in July of 2006 and the system was commissioned in December of 2006. The size of the PV system for Extrusion Technology is 60kW.

Fat Spaniel’s integrated Satcon inverter direct internet-based monitoring system was implemented and Fat Spaniel data acquisition illustrations show snapshots of the actual energy generation by the PV system for Extrusion Technology. These measurements are in compliance with the predicted analysis done by TurtleEnergy and in some cases slightly exceed the target energy output range. Data monitoring results are available both on a real-time and historical basis. Measurements can be viewed on daily, weekly, monthly, yearly or lifetime intervals. The installed PV system has successfully helped reduce the on-grid energy usage.

For additional information on product specifications see the appropriate cut sheets listed below.

Satcon 60kw Inverter

Schott ASE 315w Module

Schott FS Mounting Hardware

Fat Spaniel (remote monitoring system)

Multi-Contact Connectors

ILSCO Direct Bury Grounding Lugs

Project Data

End-User: Extrusion Technology

Installer: Sunlight Solar Energy

Location: 80 Trim Way, Randolph, MA 02368.

Date of install: June 2006 – November 2006

Size of system in kW: 60kW

Energy produced since installation

Special Challenges Met: 1) Building roof structure had to be reinforced to withstand the weight of the PV system. 2) Wind loading for the location was 110 mph.

Project Brief

Extrusion Technology is a custom specialty extrusion company, where blocks of metal are taken and forced through a die to form it into the required shape. Turtle Energy designed a Photovoltaic system to be installed on the building. The installer for the project was Sunlight Solar Energy. Due to their location in Randolph, MA Turtle Energy suggested that they use the MA made product from Schott so that they could qualify far a larger rebate from the State.

Turtle Energy undertook a detailed analysis of the site. This analysis was comprised of the following steps and implementation.

Shading Analysis

Optimal System Design and Concept Planning

Industrial Design of the Components of the System

Multi-Disciplinary Coordination with Architects, Structural Engineers, Electrical Engineers, and Construction Management.

The module and mounting hardware manufacturer provided wind analysis by a civil engineer. This analysis showed that the site required planning for 110mph wind loading consequently ballast had to be added to the Schott FS system. Gale Associates structural engineers advised that the roof structure be reinforced to ensure that it would support the PV system; this work had to be done prior to installation of the PV array.

The project commenced in July of 2006 and the system was commissioned in December of 2006. The size of the PV system for Extrusion Technology is 60kW.

Fat Spaniel’s integrated Satcon inverter direct internet-based monitoring system was implemented and Fat Spaniel data acquisition illustrations show snapshots of the actual energy generation by the PV system for Extrusion Technology. These measurements are in compliance with the predicted analysis done by TurtleEnergy and in some cases slightly exceed the target energy output range. Data monitoring results are available both on a real-time and historical basis. Measurements can be viewed on daily, weekly, monthly, yearly or lifetime intervals. The installed PV system has successfully helped reduce the on-grid energy usage.

For additional information on product specifications see the appropriate cut sheets listed below.

Satcon 60kw Inverter

Schott ASE 315w Module

Schott FS Mounting Hardware

Fat Spaniel (remote monitoring system)

Multi-Contact Connectors

ILSCO Direct Bury Grounding Lugs